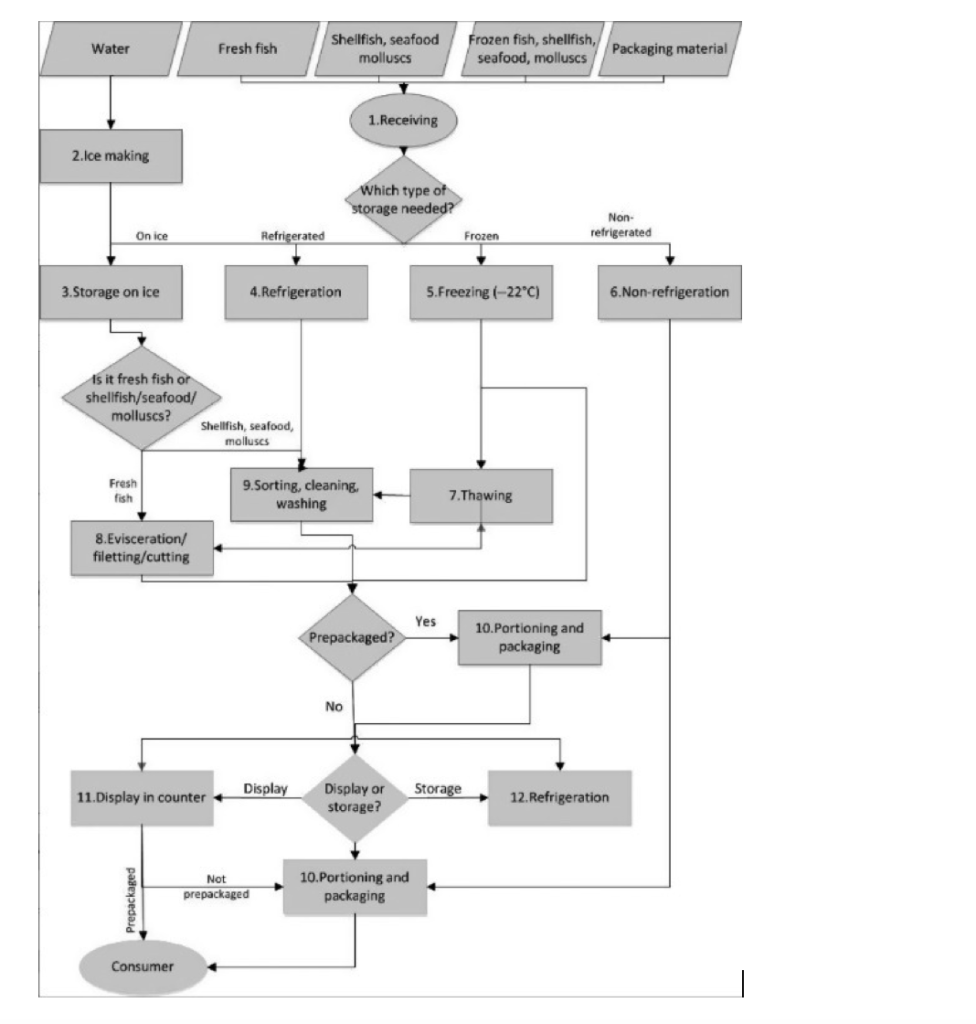

HACCP

HACCP STEP BY STEP IMPLEMENTATION TRAINING by SGS

The HACCP system was initiated in the 1960s as a result of a joint public–private venture to provide safe food for United States astronauts. In the 1980s, developed country Governments started to adopt HACCP principles. The Codex Alimentarius Commission has developed guidelines for the application of the HACCP system in food production, including a specific code of practice for fishery and aquaculture. The objective is to lower risks rather than increase inspection and testing, as testing can fail to uncover contamination in some food products even with large samples, due to the enormous variety of products and unknown probability distribution of contamination. Under these circumstances, the prevention of hazards is more effective.

The HAACP system involves seven steps, as follows:

- Conduct a hazard analysis: Identify main risks of contamination in production and distribution process

- Determine critical control points or areas where preventative steps can be applied

- Establish critical limits at each critical control point, that is, the value of indicators that trigger corrective action

- Establish critical control point monitoring requirements, including mandated procedures and their frequency for monitoring indicators at control points

- Establish corrective actions or measures to be taken in the event that critical limits are exceeded

- Establish procedures for ensuring that the HACCP system is working correctly, including regular inspections and gathering of evidence on functioning of above steps

- Establish recordkeeping and documentation of implementation of above steps. The perishability of fish products and the high risk of contamination mean that detailed HACCP measures can be judged necessary and applied at all stages of the production process, including on fishing boats, at landing sites and in storage areas, processing factories and transport facilities.